Introduction

Multitech Auto Pvt. Ltd. (MAPL) (100% subsidiary of Ramkrishna Forgings Limited) was incorporated in 1994 in Jamshedpur as a Machine Shop to supply high quality Machined part. Over the period of time, with our continuous investment in technology, training and our commitment to work, we have been able to set up a wholly owned foundry and a cold drawing Bright Bar Unit.

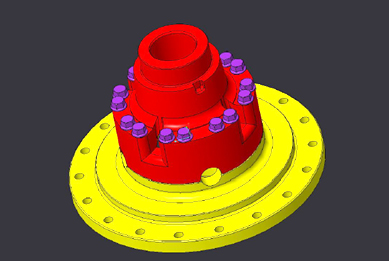

We are an IATF 16949:2016 certified company offering a wide range of hi-tech, precision machined, heat treated and ground automobile components from bars, castings, primarily for brakes, gear boxes, axle and suspension parts of commercial vehicles and railway, having extensive and modern machining facilities, SCADA Controlled Heat Treatment facilities and well equiped inspection facilities for metrological, material testing and verification.

Pioneers of ADI Castings in Eastern India

Austempered Ductile Iron Castings is a type of Ductile iron having increased Toughness, Tensile strength and Wear resistance compared to normal Ductile irons.

These properties are achieved by heat treatment of alloyed ductile iron using an Austempering process. This material offers the design engineer the best combination of low cost, design flexibility, good machinability, high strength-to-weight ratio and good toughness, wear resistance and fatigue strength

ADI offers this superior combination of properties since it can be cast like any other member of the Ductile Iron family, offering all the production advantages of a conventional Ductile Iron casting.

The Austempering process results in mechanical properties that are superior to conventional ductile iron, cast and forged Aluminum and many Cast and Forged steels hence offering a substantial Cost Savings with increased benefits.